3D micro fluidics for medical diagnosis

Microfluidics in glass and in 3D - prototypes and series available

We produce for you micro-channels in fused silica with our SLE technology. Advantages of the material are good optical transparancy, biological compatibleness and chemical resistiveness.

Processes like glueing or bonding are not necessary anymore since we produce three dimensional structures directly inside the glass with the SLE technology. This keeps the cells in safe custody from glues and ensures long-lasting stability of your bio-chip.

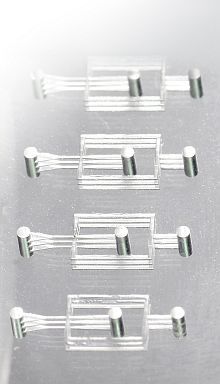

We produce for you prototypes and series of your bio-chip directly from your CAD data. We gladly assist you in the preparation of the 3D-CAD models accordant to your wishes.

To enable mass production of your bio-chip design we assist you in the integration of our high speed microscanner in your production line. For further cost-reduction we help you to process cost-effective float glasses and we optimize our microscanner to produce your chip-design with high throughput.

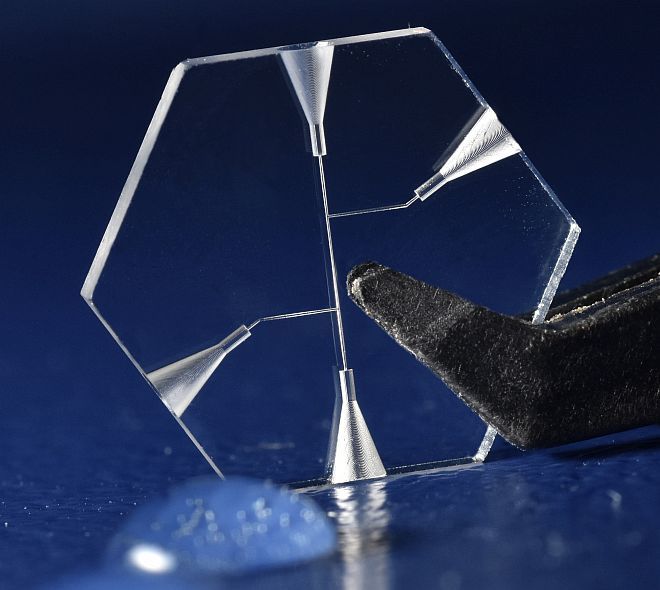

Micro fluidics become three dimensional now - without additional expenses

With our SLE-Technology and our Microscanners we print complex microfluidics directly from your 3D-CAD data in fused silica glass. Now you can design your bio-chip with bridges to enable additional features and to save space at the same time.

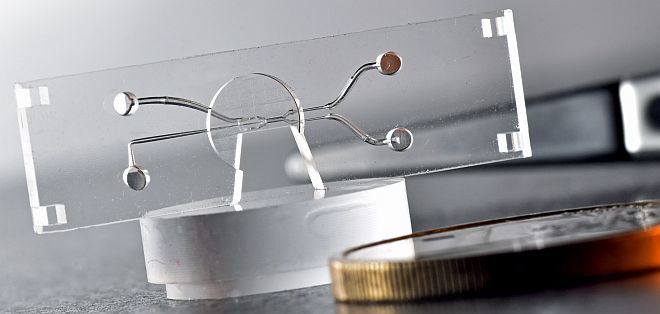

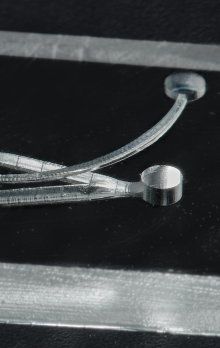

There is no need anymore to glue connectors for flexible tubes on your biochip - the connectors are printed together with the channels inside the glass (see picture below).

Micro channels with narrowings or widenings are no problem in all three dimensions. Branchings and reaction chambers are possible; we even have mounted a rotatable gear inside the tunnel to demonstrate the new possibilities.

The roughness of the micro channels is about Rz~1 µm (top-to-valley). After the micro channel is filled with liquid, the optical quality is improved by immersion and sufficient e.g. for fluorescence microscopy. The length of a tunnel can be more than 10 mm between two connections to the surface. The minimal height of such a channel is ~30 µm and the minimal width ~ 10 µm. The total structure is restricted to 2-7 mm depth inside the glass, because that is the depth accessible for common long-distance microscope objectives.

Buried microchannel branching with high precision