Assembled micro mechanics and cylindrical drilling in fused silica

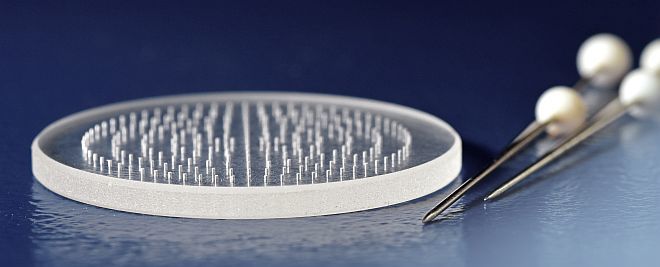

With the SLE-technology we produce for you micro drillings and micro mechanical components in fused silica. Advantages are optical transparency, chemical and mechanical resistiveness of this glass material.

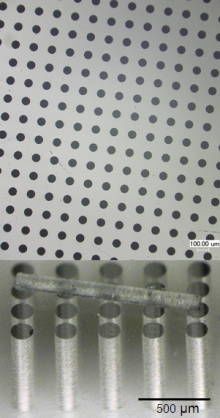

No assembly of micro-structured parts is necessary anymore, since the complex 3D structures are produced directly inside the glass. For example a rotatable gear is produced already mounted on its axis (see picture below) or even mounted inside a buried micro channel.

Inside a work piece with a height of 2 mm we achieve a precision of about 2 µm, minimal gap width of 10 µm, minimal gap height of 20 µm and a taper of less than 20 µm. The roughness of the walls inside the glass is about 1 µm Rz (top-to-valley).

We produce for you prototypes and series of your glass part directly from your CAD-data. We gladly assist you in preparing the 3D-CAD models according to your needs.

For mass-production of your micro structured glass part we assist you in the integration of our modular high speed micro scanner with translation stages and state-of-the-art high power ultrafast lasers into your production system.

We offer to optimize our micro scanner for high throughput of your product and assist you in the process development for other materials.

Fabrication of direct assembled 3D micro mechanical parts in glass