Job-Shop

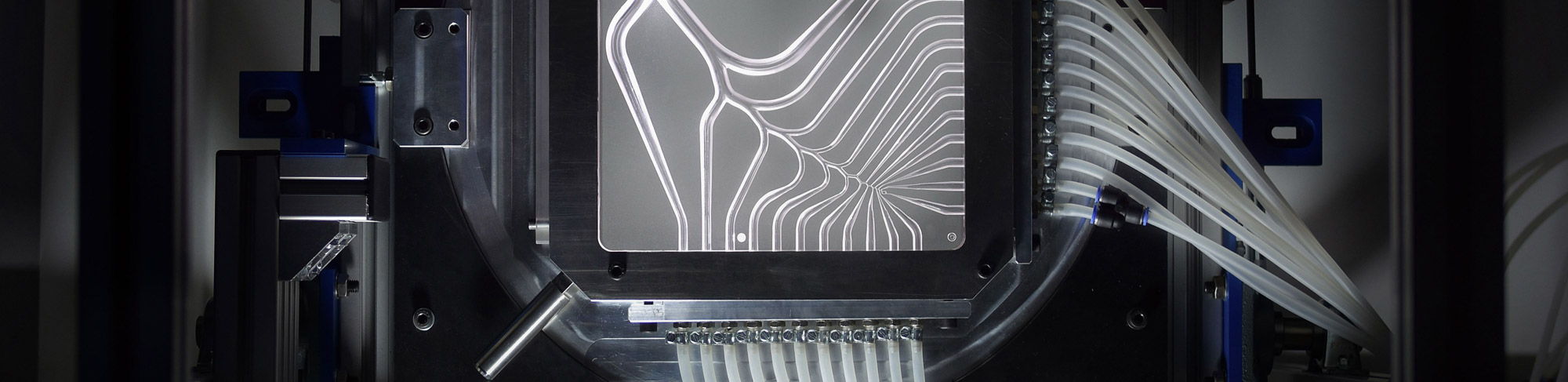

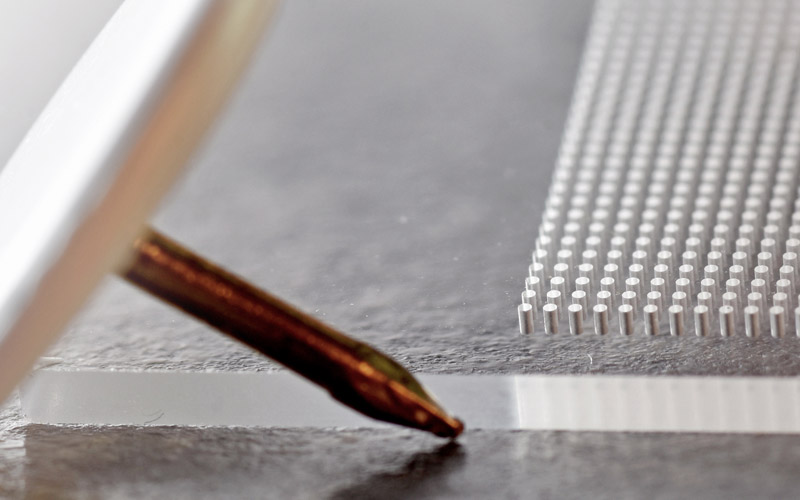

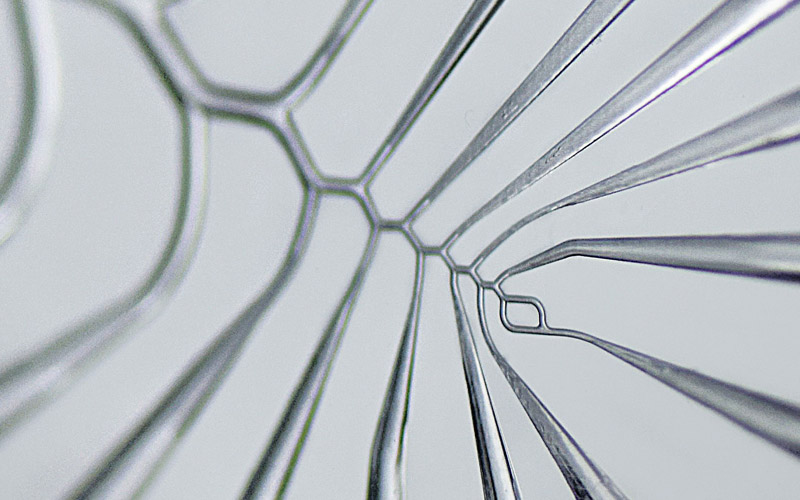

By using SLE technology, we produce micro-drilled holes and micromechanical components in quartz glass for you. The advantages of this material include optical transparency and chemical and mechanical resistance.

With a component height of 2 mm, we achieve a precision of 2 µm, minimum gap widths of approximately 10 µm, gap heights of 20 µm, and a conicity of no more than 20 µm. The roughness of the walls is approximately 1 µm Rz.

There is no need to assemble the microstructured components because SLE technology allows three-dimensional structures to be produced directly in the glass. For example, we manufacture a rotatable gear wheel that is already mounted on its axis.

We manufacture prototypes and series of your glass components , directly from your CAD data. We are happy to assist you in creating 3D CAD models according to your requirements.

Contact

Please fill out the following form and send us your request. We'll get back to you as soon as possible.