SLE process

The SLE (Selective Laser-Induced Etching) process is a two-stage process:

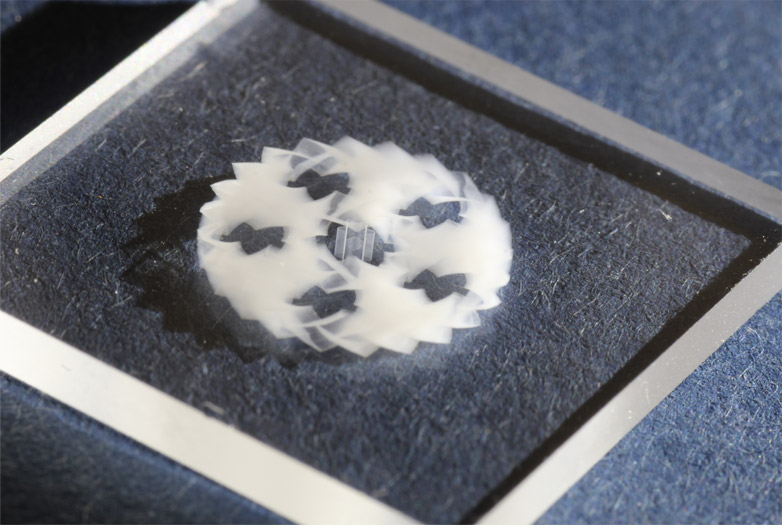

First, transparent material is exposed to laser radiation in such a way that the chemical etchability is increased at these points. To ensure that this is achieved without cracking, a short pulse duration (fs-ps) and a small focus volume (a few µm3) are required. The focus is then moved through the material until a contiguous volume in contact with the outer surface of the workpiece is exposed.

In the second process step, the material modified by the laser radiation is selectively removed by wet chemical etching—the structure is essentially developed. Selectivity—the etching rate of the modified material in relation to the etching rate of the unmodified material—is essential for structural accuracy.

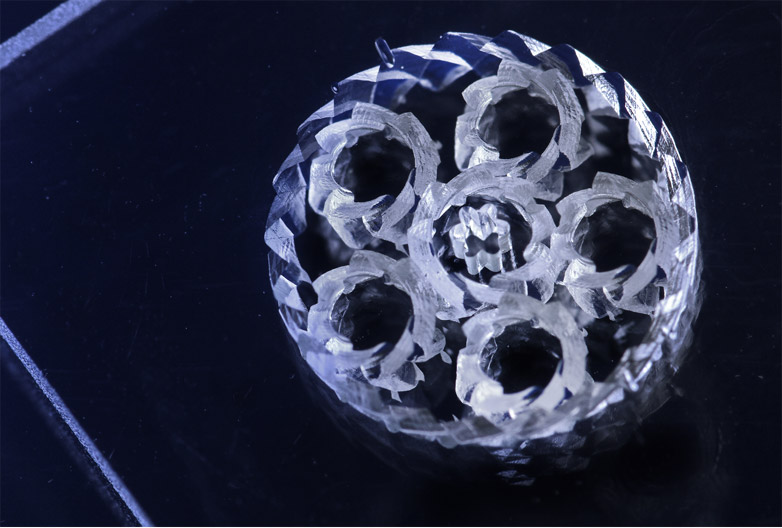

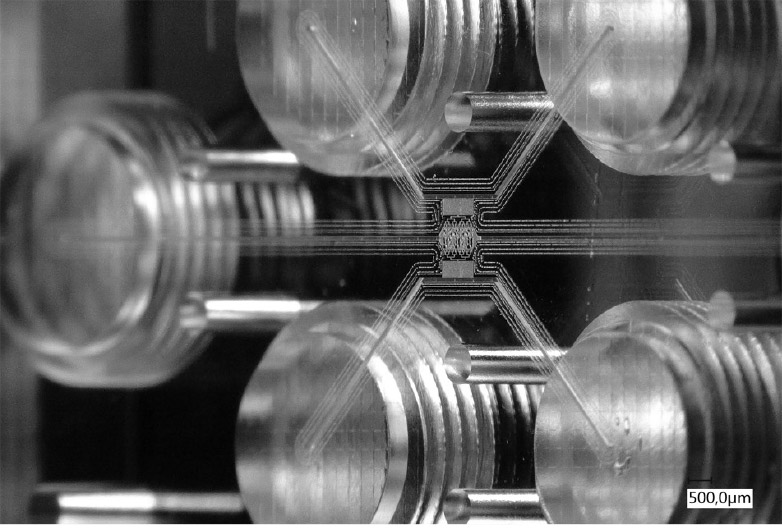

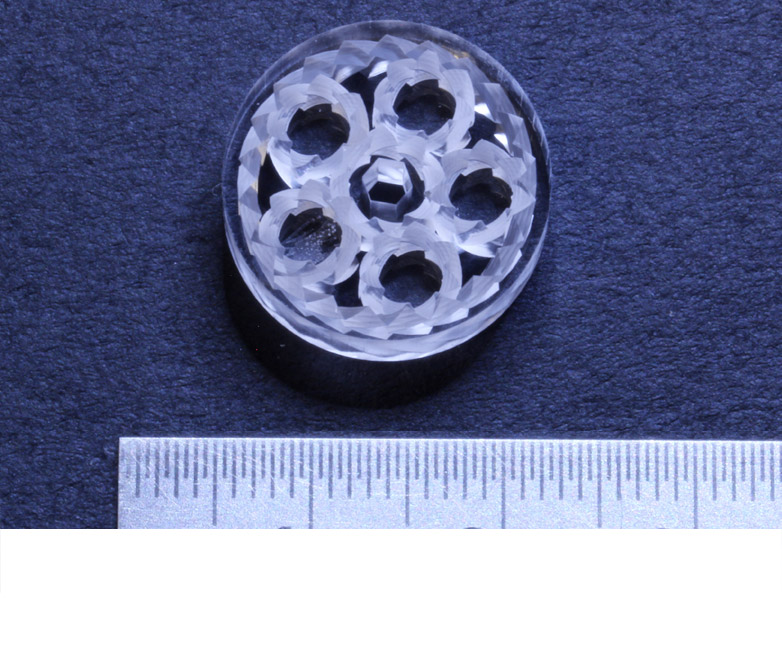

Quartz glass typically has a selectivity greater than 500:1, enabling the creation of fine, long channels with low conicity (see image below). SLE technology can therefore be used to create complex 3D cavities in glass, which form the basis for our products, such as microfluidics and microstructured components.

Thanks to its

- high precision (~ 1µm)

- full 3D capability

- and high processing speed achieved through he use of our microscanners

the SLE technology is ideally suited for the digital 3D printing of glass components.

Downloads | Links

Contact

Please fill out the following form and send us your request. We'll get back to you as soon as possible.