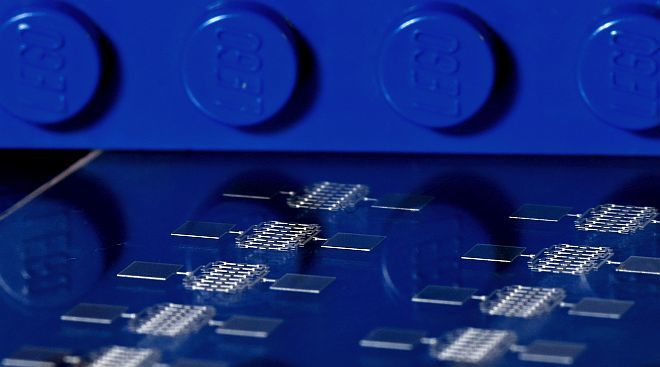

Our Technology: Microscanner and the SLE-process

Our micro scanner with micrometer focus offer the crack-free structuring of transparent materials with ultrafast fiber lasers and enable the efficient production of 3D glass components using the SLE technology (selective laser-induced etching).

The SLE-process is a subtrative 3D printing process similar to 3D lithography - but we use quartz glass as the positive tone resist. Advantages compared to additive printing are much larger precision (~1 µm), more design freedom (no need for supporting structures), and well known materials properties: The material of the product is the same as in the data sheet, since all laser treated material is removed by the etching step - no pores nor strain nor bond flaws. Therefore, we have a lot of customers ordering 3D glass precision parts just because similar parts are not possible with metal additive 3D printing.

Our high speed micro scanner are suitable to exploit the potential of high power ultrafast lasers for high throughput production. The high average power of those lasers make a large feed rate necessary - for most practical applications the large velocity is ensured on curved tracks with small curvature. High speed scanning with micro meter focus provides new processing parameters for our SLE process to optimize throughput.

To open up new vistas for your investment in research and development we manufacture for you not only prototypes and small series of your designs but open for you the perspective, to produce your design for the mass market with our high speed micro scanners.

To be able to optimize throughput we build our high speed micro scanners consequently modularly. We are able to exploit and the fastest means of laser beam motion to produce your structure most cost effective. Our CAM software controls not only our micro scanner modules but also various commercial positioning systems and laser systems and we would like to adapt it to control your systems.

Our LightFab 3D Printer is fast enough to produce ~10,000 3D glass precision parts per year. But it would be a waste of resources to always do the same thing with an extremely flexible digital printer. Thus for mass-production of a 3D glass precision part we engineer a special machine and optimize the process to make this part much faster. So we combine a tailored choice of our high speed scanning modules, e.g. one which writes very fast a straight line and another one which makes a fast circle and a third one with fast arbitrary movements of very short length. We synchronize the modules and produce special CAM software to optimize the throughput. This high-speed 3D Microscanner is not a 3D printer anymore since we disclaimed flexibility to gain productivity by a factor of 50-100 and enable mass-production of a million parts per year with a single special machine.